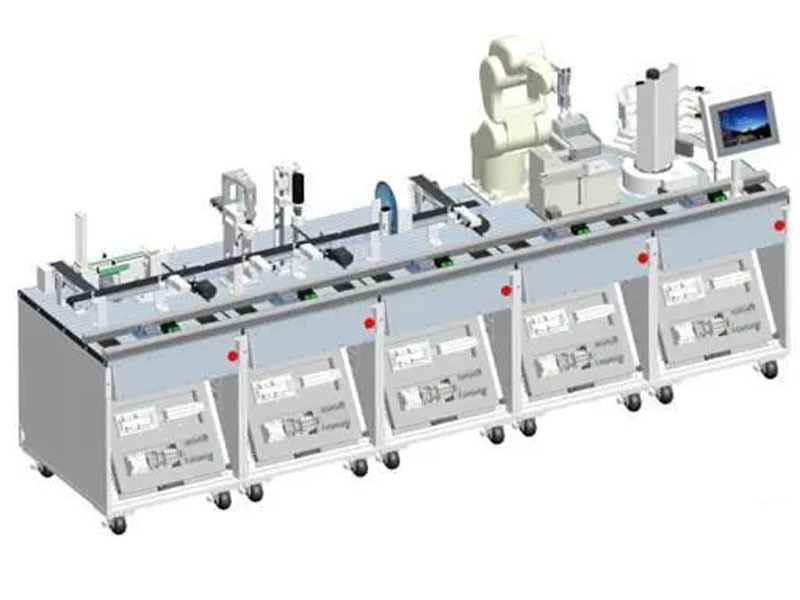

Filling automated production line training device, filling automated production line training equipment

Release Time: 2023-04-22 16:11:11.159

MY-18F filling automation production line training device is a most typical mechatronics, automation products, it is for vocational colleges, education and training institutions and other development, it is suitable for mechanical manufacturing and its automation, mechatronics, electrical engineering and automation, control engineering, measurement and control technology, computer control, automation control and other related professional teaching and training. It is close to the industrial production and manufacturing site, and the dual-purpose practical training teaching is specially designed, which strengthens various control and engineering practical capabilities. The system includes pneumatic, motor drive and control, PLC, frequency converter, touch screen, sensor and other control technologies in mechatronics majors, which is suitable for engineering practice, course design and training of engineering and technical personnel who have just started in related majors.

2025. Product overviewFilling

automation production line closely combines the "Made in China <>" and "National Medium and Long-term Talent Development Plan Outline" for the training requirements of "intelligent manufacturing" and innovative scientific and technological talents in urgent need of "intelligent manufacturing" and key areas of economic and social development, and is developed and designed in accordance with the relevant standards and procedures of the Worldskills Competition in accordance with the national training and appraisal standards for relevant occupational types and combined with the job needs of China's current manufacturing industry. The system comprehensively reflects mechatronics automatic production, industrial robot automation "work cell", and other auxiliary work facilities in the form of "working station", and operators can cultivate training automation professional skills, robot automation skills, world-class competition requirements, etc. in the form of "working station", and can also improve the social ability and method ability in professional quality.

The equipment is composed of filling and feeding workstation, capping and capping workstation, detection and sorting workstation, industrial robot packaging workstation, finished product automatic warehousing workstation, including intelligent assembly production system, automatic packaging system, automatic three-dimensional warehouse and intelligent warehousing system, automatic detection machine quality control system, production process data acquisition and control system, etc., is a complete intelligent factory simulation device, the application of industrial robot technology, PLC control technology, step control technology, Servo control technology, industrial sensor technology, motor drive technology and other industrial automation related technologies, can realize the automatic feeding of empty bottles, the variety of granular material feeding, automatic sorting of materials, optional filling of granules, automatic capping, automatic capping, finished product detection, finished product sorting, robot grabbing into the box, box cover packaging, automatic warehousing and other intelligent production processes.

2. Technical parameters

1. System power supply: 220V 2. Equipment weight: 360kg

3. Rated voltage: AC220V

±5% 4. Rated power: 3.6KW

5. Ambient humidity: ≤90%

6. Equipment size: 420cm×72cm×150cm (length×width × height)

7. Safety protection function: emergency stop button, leakage protection, overcurrent protection.

8. PLC: Siemens S7-1200

9. Servo: Siemens V90/motor SIMOTICS S-1FL6 10. Touch screen: MT8101IE+MT-FX3M

11, stepper motor: drive SR2/motor AM17HD6426-06N

12. Robot: ABB IRB120 robot

three, filling and feeding station

1, workstation introduction

The feeding belt conveys the empty bottles to the main conveyor belt one by one; At the same time, the granular feeding mechanism pushes out the materials in the barrel; The granular sorting mechanism sorts the granular materials according to the color; When the empty bottle reaches the filling position, the belt stops, and the positioning clamping mechanism fixes the empty bottle; The suction mechanism will suck the granular material sorted in place and put it into the empty bottle; After the material in the bottle reaches the set number of particles, the positioning clamping mechanism is loosened, the belt is activated, and the bottle is transported to the next station. This unit can be equipped with a variety of filling methods, and 8 filling methods can be generated by combining different combinations of material color (2 types) and particle quantity (up to 4 grains).

2. Main technical parameters

CPU (1214C DCDCDC): brand Siemens, 14 points integrated 24V DC digital input, 10 points integrated digital output, 2 points integrated analog input, 0 to 10 V, 2 points pulse output (PTO), frequency up to 100 kHz, pulse width modulation output (PWM), frequency up to 100 kHz, integrated Ethernet interface (TCP/IP native, ISO-on-TCP), removable terminals on all modules.

DC geared motor (Z2D1024GN-18S-2GN75K): 24VDC; Reduction ratio 1/75;1800Rpm; 0.45Kg.cm;0.69A;GN gear shaft type.

Rotary cylinder (HRQ10): brand AirTAC, double piston rack and pinion compound type; Bore 10; Swing angle range 0-190°; Repeatability 0.2°; Torque 1.1Nm, pipe diameter M4*0.8, oil pressure buffering.

Fiber amplifier (E3X-HD41): brand OMRON, PNP output; VR adjustment (coarse/fine); Response time less than 1ms; 12-24VDC power supply; Red LED light source; The length of all kinds of cables is 2m; Size 15*39*73mm.

Fiber head (E32-ZD200): brand OMRON, diffusion reflection type, threaded type, M6, end view 0.005560100, standard type 2 m free cut, suitable for positioning M8 (approx. 18g)

fiber head (E32-ZD200E): brand OMRON, diffusion reflection type, threaded type, M3, end view with lens 0.005 200 32 non-breaking strength and toughness flexible 1 m, free cut M3 , If used with F-2HA using light spot diameter 0.4 (about 6g)

switching power supply (Siemens switching power supply 5A): double output 24VDC; Rated 150W/6.2A.

Circuit breaker (EA9AN2C10A): 2 poles; Rated 10A; C-type trip characteristics.

Induction switch: two-wire type; Reed type with contact; normally open type; Cable length 2m; 5-30VDC power supply; Red LED indication; Scope of application G type (for MD, MK, TR, TC, ACP, ACQ, STM, TWH (M), TWQ, SDA cylinder)

IV. Capping and capping workstation 1, workstation

introduction

Receive the bottle filled with granules at the previous station, when the bottle is transported to the capping mechanism, the main conveyor belt stops, the clamping mechanism positions the clamping mechanism to fix the bottle, the capping mechanism starts the capping process, and the cap is added to the bottle; After adding the lid, the main conveyor belt starts, and the bottle with the cap continues to be sent to the capping mechanism, to the bottom of the capping mechanism, the main conveyor belt stops, the capping positioning clamping mechanism fixes the bottle, the capping mechanism starts, the cap is tightened, the main conveyor belt starts, and the material bottle with the screwed cap is transported to the next station. Caps are available in white and black.

2. Main technical parameters

CPU (1214C DCDCDC): brand Siemens, 14 points integrated 24V DC digital input, 10 points integrated digital output, 2 points integrated analog input, 0 to 10 V, 2 points pulse output (PTO), frequency up to 100 kHz, pulse width modulation output (PWM), frequency up to 100 kHz, integrated Ethernet interface (TCP/IP native, ISO-on-TCP), removable terminals on all modules.

CPU Extension (SM1221): Brand Siemens, 16×24VDC input current sink/current source.

CPU Extension (SM1222): Brand Siemens, 8×24VDC output current source.

DC geared motor (Z2D1024GN-18S-2GN75K): 24VDC; Reduction ratio 1/75;1800Rpm; 0.45Kg.cm;0.69A;GN gear shaft type.

Capping motor (ZGX45RGG DC24V): 24VDC; Reduction ratio 1/22.5, diameter 45; Rated speed: 2.4, (rpm) r/min; 0.47A; Permanent magnet DC planetary gear motor.

Pen cylinder (PB-10X80-S-U): brand AirTAC, compound type; bore Ф10; Stroke 80mm; Magnet attached; Radial intake type; axial retention mechanism; Internal thread M5*0.8;Anti-collision pad cushioning.

Fiber amplifier (E3X-HD41): brand OMRON, PNP output; VR adjustment (coarse/fine); Response time less than 1ms; 12-24VDC power supply; Red LED light source; The length of all kinds of cables is 2m; Size 15*39*73mm.

Fiber optic head (E32-ZD200): brand OMRON, diffusion reflection type, threaded type, M6, end view 0.005560100, standard type 2m free cutting, suitable for positioning M8 (about 18g)

switching power supply (Siemens switching power supply 5A): double output 24VDC; Rated 150W/6.2A.

Circuit breaker (EA9AN2C10A): 2 poles; Rated 10A; C-type trip characteristics.

Induction switch: two-wire type; Reed type with contact; normally open type; Cable length 2m; 5-30VDC power supply; Red LED indication; Scope of application G type (for MD, MK, TR, TC, ACP, ACQ, STM, TWH(M), TWQ, SDA cylinder)

five, detection and sorting workstation 1, workstation

introduction

The main belt runs, receives the material bottle after the previous station screwed the cap, when the material bottle passes through the detection mechanism: the return reflection sensor detects whether the cap is tightened; The testing agency detects whether the particles inside the bottle meet the requirements; Distinguish the color of the cap for bottles with both screwed caps and particles; Bottles with unscrewed caps or unqualified pellets are pushed onto the waste belt (short belt) by the sorting mechanism; Bottles with screwed caps and granules are transported to the end of the belt and awaiting robot handling.

2. Main technical parameters

of twin-shaft cylinder (TR-16X125-S): compound type; bore Ф12; Stroke 125mm; Magnet attached; Copper sleeve bearings; Internal thread M5*0.8;Anti-collision pad cushioning.

Pressure regulating filter: medium air; Internal thread PT1/4, differential pressure drainage type; MPA scale; Water filter cup capacity 15CC

gas solenoid valve: five ports and two positions; Pilot-operated; Dual position dual electronic control; Female thread M5; Working voltage 24VDC; DIN socket type; Aluminum alloy; Pressure range 0.15-0.8Mpa; medium air.

CPU (1214C DCDCDC): Brand Siemens, 14 points integrated 24V DC digital input, 10 points integrated digital output, 2 points integrated analog input, 0 to 10 V, 2 point pulse output (PTO), frequency up to 100 kHz, pulse width modulation output (PWM), frequency up to 100 kHz, integrated Ethernet interface (TCP/IP native, ISO-on-TCP), All modules are removable terminals.

CPU Expansion (SM1221): Brand Siemens, 16×24VDC Input Current Sink/Current Source.

CPU Extension (SM1222): Brand Siemens, 8×24VDC Output Current Source.

DC geared motor (Z2D1024GN-18S-2GN75K): 24VDC; Reduction ratio 1/75;1800Rpm; 0.45Kg.cm;0.69A;GN gear shaft type.

Fiber amplifier (E3X-HD41): brand OMRON, PNP output; VR adjustment (coarse/fine); Response time less than 1ms; 12-24VDC power supply; Red LED light source; The length of all kinds of cables is 2m; Size 15*39*73mm.

Fiber head (E32-ZD200): brand OMRON, diffusion reflection type, threaded type, M6, end view 0.005560100, standard type 2 m free cut, suitable for positioning M8 (approx. 18g)

fiber head (E32-ZD200E): brand OMRON, diffusion reflection type, threaded type, M3, end view with lens 0.005 200 32 non-breaking strength and toughness flexible 1 m, free cut M3 , If used with F-2HA using light spot diameter 0.4 (about 6g)

switching power supply (Siemens switching power supply 5A): single output 24VDC; Rated 150W/6.2A.

Circuit breaker (EA9AN2C10A): 2 poles; Rated 10A; C-type trip characteristics.

Induction switch: two-wire type; Reed type with contact; normally open type; Cable length 2m; 5-30VDC power supply; Red LED indication; Scope of application G type (for MD, MK, TR, TC, ACP, ACQ, STM, TWH (M), TWQ, SDA cylinder)

256 color indicator (BNI0072): 256 color indicator light, can be used as equipment operation indication and remote IO learning.

6. Industrial robot packaging workstation 1, workstation

introduction

AB two lifting tables respectively store the bottom of the packaging box and the cover of the packaging box; After the industrial robot packaging workstation is started, the A lifting table pushes the bottom of the packaging box to the material table, and the A lifting table rises a box bottom position; Wait for the material bottle that passed the test at the previous station to be in place, and when the qualified material bottle of the previous station is in place, start the industrial robot to grab the bottle and put it into the bottom of the packaging box on the material table; When the 4 stations at the bottom of the packaging box are filled with bottles, the industrial robot automatically draws the box lid from the B lifting table, covers it on the packaging box, and the B lifting table then rises a box lid position, and notifies the finished product automatic warehousing workstation to enter the warehouse.

2. Main technical parameters

robot (IRB120): ABB brand, horizontal extension distance 580mm, maximum load 3kg, body weight 25kg, self-weight load ratio 4.8, cable length 7m connected to the control cabinet, 6 degrees of freedom, repeatability accuracy ± 0.01mm, maximum speed of working range: J1≧±165?(250?/s) J2≧+110?~-110? (250?/s) J3≧+70?~-90?(250?/s) J4≧±160?(320?/s) J5≧±120?(320?/s) J6≧±400?(420?/s)

Robot controller: ABB brand IRC5 model, dimensions (L/WxH) 258 x450 x 565mm, weight 27.5kg, External interface: input/output: standard 16/16 (up to 8192) Digital: 24VDC or relay signal, Analog: 1×0-10V, serial channel: 1×RS 232 (RS422 with adapter), Network: Ethernet (10/100 MB/s), two channels: service and LAN, Fieldbus (master) :D eviceNet, PROFINET, PROFIBUS DP, Ether net/IP, fieldbus (slave) :P ROFINET, PROFIBUS DP, Ether net/IP, Interbus, Allen-Bradley remote I/O, CC-link, processing encoder up to 6 channels, power supply 200~240VAC, 50~60Hz, etc.

Teach pendant: ABB brand, weight 1kg, 6.5" graphical color touch screen, joystick, emergency stop, support left/right hand switching, support U disk, maintenance, diagnostic software, recovery program, login with time stamp, support remote service.

Stepper motor driver: input voltage 12-48VDC; Input signal voltage 4-28VDC; Input current 0.3-2.2A; step pulse frequency 2-2MHz; 3-bit DIP switch; 8 kinds of current subdivision selection

CPU (1214C DCDCDC): brand Siemens, 14 points integrated 24V DC digital input, 10 points integrated digital output, 2 points integrated analog input, 0 to 10V, 2 point pulse output (PTO), frequency up to 100kHz, pulse width modulation output (PWM), frequency up to 100 kHz, integrated Ethernet interface (TCP/IP native, ISO-on-TCP), removable terminals on all modules.

CPU Extension (SM1221): Brand Siemens, 16×24VDC Input Current Sink/Current Source.

CPU Extension (SM1222): Brand Siemens, 8×24VDC Output Current Source.

Switching power supply (Siemens switching power supply 5A): single output 24VDC; Rated 150W/6.2A.

Circuit breaker (EA9AN2C10A): 2 poles; Rated 10A; C-type trip characteristics.

Induction switch: two-wire type; Reed type with contact; normally open type; Cable length 2m; 5-30VDC power supply; Red LED indication; Scope of application G type (for MD, MK, TR, TC, ACP, ACQ, STM, TWH (M), TWQ, SDA cylinder)

pressure regulating filter: medium air; Internal thread PT1/4, differential pressure drainage type; MPA scale; Water filter cup capacity 15CC

gas solenoid valve: five ports and two positions; Pilot-operated; Dual position dual electronic control; Female thread M5; Working voltage 24VDC; DIN socket type; Aluminum alloy; Pressure range 0.15-0.8Mpa; medium air.

Seven, finished products automatic warehousing workstation 1, workstation introduction

is composed of an arc three-dimensional warehouse and 2-axis servo stacking mechanism, when the industrial robot workstation

completes the packaging task, receive the signal to absorb the packaging box on the material table of the robot workstation, and then put into the corresponding warehouse according to the requirements. Each warehouse of 2×3 is equipped with a detection sensor, the horizontal axis of the stacking mechanism is the precision indexing plate mechanism, and the vertical mechanism is the turbine screw lifting mechanism, all of which are controlled by Siemens V90 precision servo motor with high precision.

2. Main technical parameters V90 servo control: brand Siemens, integrated all control modes: external pulse position control, internal setpoint position control, speed control, torque control, integrated holding brake relay, 1MHz high-speed pulse input, 20-bit resolution absolute value encoder, can be copied through SD card parameters

, etc.

V90 servo motor: brand Siemens, rated speed 2000rpm, rated torque 1.27NM, absolute encoder 20-bit resolution, protection class IP65 self-cooling.

Vacuum generator: direct piping type (no muffler); Nozzle diameter Ф0.5, maximum vacuum +88kPa; SUP interface Rc1/8, VAC interface Rc1/8, EXH interface Rc1/8

suction cup: vertical vacuum port nozzle; without buffering; Ф10 parallel suction cups; NBR; Pipe type male thread; Thread diameter M5*0.8

CPU (1214C DCDCDC): Brand Siemens, 14 points integrated 24V dc digital input, 10 points integrated digital output, 2 points integrated analog input, 0 to 10 V, 2 pulse output (PTO), frequency up to 100 kHz, pulse width modulation output (PWM), frequency up to 100 kHz, integrated Ethernet interface (TCP/IP native, ISO-on-TCP), removable terminals on all modules.

CPU Extension (SM1221): Brand Siemens, 16×24VDC Input Current Sink/Current Source.

CPU Extension (SM1222): Brand Siemens, 8×24VDC Output Current Source.

Switching power supply (Siemens switching power supply 5A): single output 24VDC; Rated 150W/6.2A.

Circuit breaker (EA9AN2C10A): 2 poles; Rated 10A; C-type trip characteristics.

Induction switch: two-wire type; Reed type with contact; normally open type; Cable length 2m; 5-30VDC power supply; Red LED indication; Scope of application G type (for MD, MK, TR, TC, ACP, ACQ, STM, TWH (M), TWQ, SDA cylinder)

pressure regulating filter: medium air; Internal thread PT1/4, differential pressure drainage type; MPA scale; Water filter cup capacity 15CC

gas solenoid valve: five ports and two positions; Pilot-operated; Dual position dual electronic control; Female thread M5; Working voltage 24VDC; DIN socket type; Aluminum alloy; Pressure range 0.15-0.8Mpa; medium air.

8. Man-machine interface 1, man-machine interface

introduction 7-inch

widescreen touch is installed in the finished product warehousing unit, and the filling automation production group controller PLC connection communication, display the equipment required parameter settings, equipment start and stop, displayIO signals between stations, hardware IP, etc.

More News

Exhibition Information | The 29th (2023) China International Packaging Industry Exhibition

Exhibition Information: The 29th (2023) China International Packaging Industry Exhibition

Exhibition Information | The 29th (2023) China International Packaging Industry Exhibition

Exhibition Information: The 29th (2023) China International Packaging Industry Exhibition

Exhibition Information | The 60th China (Guangzhou) International Beauty Expo

The 60th China (Guangzhou) International Beauty Expo

Filling automated production line training device, filling automated production line training equipment

MY-18F filling automation production line training device is the most typical mechatronics and automation products, it is developed for vocational colleges, education and training institutions, etc., it is suitable for machinery manufacturing and its automation, mechatronics , electrical engineering and automation, control engineering, measurement and control technology, computer control, automation control and other related professional teaching and training. It is close to the industrial production and manufacturing site and is specially designed for practical training and teaching, which strengthens various control and engineering practice capabilities. The system includes pneumatic, motor drive and control, PLC, frequency converter, touch screen, sensor and other control technologies in the mechatronics major. It is suitable for students of related majors to carry out engineering practice, course design and training for engineering and technical personnel who are new to the post. .

The fully automatic juice seasoning liquid filling production line is easy to operate

The fully automated juice seasoning liquid filling production line is easy to operate, and what is more noteworthy is that the equipment performance is stable and reliable, which greatly reduces the overall investment of your enterprise and completely saves labor costs. The production cost of users is reduced, and the fully automatic filling production line of juice and seasoning liquid is also anti-corrosion equipment, which meets the production needs of more customers.

Automated pepper sauce filling production line saves one person

The automatic pepper sauce filling production line has high production efficiency. It is very convenient for sauce products in the enterprise. The automatic pepper sauce filling production line has stable performance and simple operation. It only needs one person, allowing you to start from A series of processes such as bottle unscrambling, bottle washing, drying, filling, capping, labeling, and boxing are completed independently, allowing your business to become formal, freeing your hands, and saving you a lot of labor costs.

Address: Building B7, Fengsheng Keyuan, No. 100, Beilong Road, Dagang Town, Nansha District, Guangzhou City, Guangdong Province

Tel:020-84999703 84991597 34982803(Switchboard)

Foreign Trade:+86-020-39273262 +86-020-39273592

Fax:020-84991597

Email:sfdqbz@163.com

Follow the WeChat public Account

Scan and preview mobile terminal

Email: sfdqbz@163.com

I look forward to hearing from you

Contact:

Domestic:020-84999703 / 020-84991597 / 020-34982803

Foreign trade:+86-020-39273262 / +86-020-39273592